Information

IoT project for improving productivity of eyewear manufacturing

2017.04.15

Few days ago, Mr. Imoto, a professional of IoT (Internet of Things) and the president of Media-Sketch, came to Fukui Sabae area.

That is because we are in danger of decline of production capacity which is due to recession of economy and decreasing of Japanese working-age population.

In addition, high quality and complicated design eyeglasses are becoming popular recently, and we get too many orders to make all by domestic and international companies because only Fukui Sabae can make it.

That is why Fukui Optical Industrial Association started this project for “improving our productivity”.

The process is inviting a professional, and he investigate the possibility of improving productivity by IoT technology, then we share the result with all companies in Fukui Sabae.

The purpose is

“making higher quality eyeglasses by limited craftsmen in short term”.

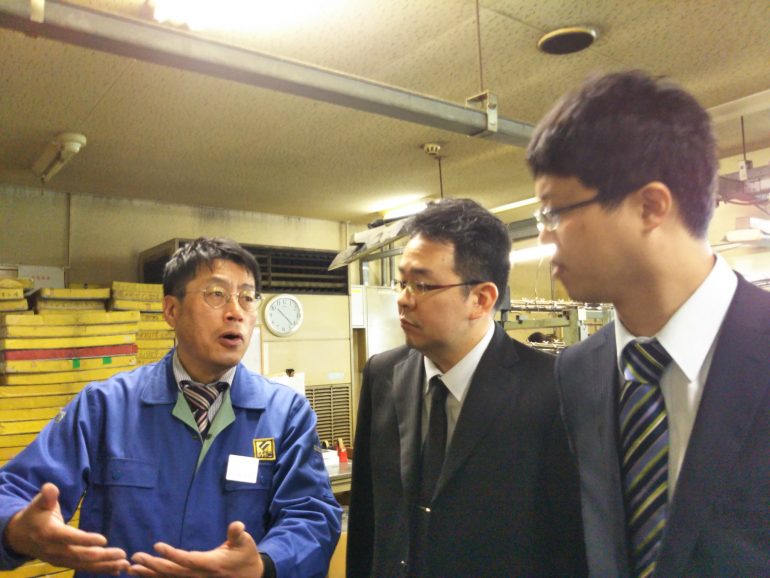

One TV media accompanied with our first factory inspection by Mr. Imoto on Apr. 11-12th.

We went to 3 different types of manufacturers so that Mr. Imoto can understand how to make high quality eyeglasses in Fukui Sabae.

After the inspection, Mr. Imoto said two impressive things.

#1. We can use IoT much easier than you have expected.

#2. IoT does not take the place of craftsmen, but assist them.

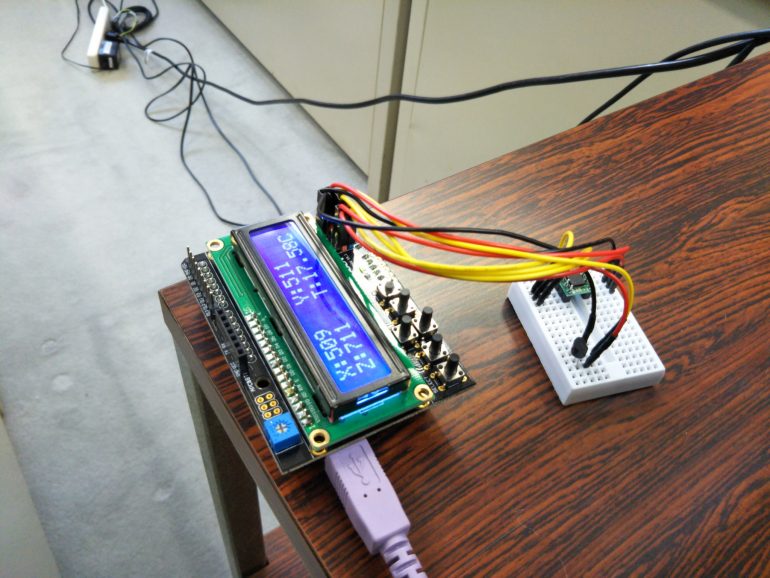

As for #1, for example, the small computer and sensor below are able to measure temperature, inclination and vibration immediately.

And we are surprised that it costs less than 100 US dollars. It make us feeling familiar with IoT.

As for #2, if the process of making eyeglasses can be replaced by machines, China and other developing country can easily do it.

However, making high quality eyeglasses definitely needs master craftsmen’s skill and sense.

For example, sensor distinguish “products with scratch” and “perfect products” after machinery polishing, then craftsmen polish only the former products.

Of course Mr. Imoto gave us a lot of other advice too, and we found that there is many possibilities to improve our productivity.

This project is supported by organizations below.

IPA (Information-technology Promotion Agency)

Fukui-pref IoT Acceleration Lab

We really appreciate them.

This project is just a beginning now.

We would like to research what manufacturers can do concretely, and carry out it step by step.

Thank you for reading.

New Information