Glasses Master Craftsmen and Skills

Providing Maximum Comfort for Long-Term Use.

In many cases, it can take up to 200 or more processes to complete a pair of world-class Fukui Sabae glasses. Each individual process is a division of labor involving dedicated factories and skilled craftsmen. Although the individual craftsmen are engaged in different processes, strict quality checks and control result in superior quality glasses.

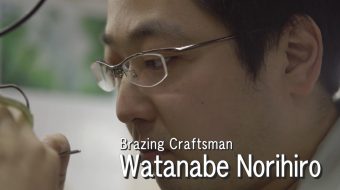

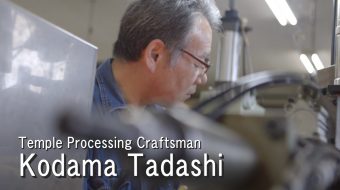

Although machinery has optimized production, the majority of important processes are still performed by the trained eyes and skilled hands of our craftsmen. Extremely high-precision, user-friendly glasses cannot be produced with machines alone.

The individual craftsmen may be engaged in different processes, yet each continue to produce glasses with the same shared dream and sense of purpose.

To provide maximum comfort for long-term use.

Glasses play a major role in our everyday lives. For that reason, they must be strong, and offer such superior levels of comfort that users will forget they are wearing them. Each skilled craftsmen passes on this desire and sense of purpose to the next process.

Process of Craftsmanship

Metal 1 - Craftsman, Design

"How can I express myself in such a limited space,and design something that will feel good to wear?"

Metal 2 - Craftsman, Die Making

"There are times when glasses don't turn out how we intended in our drawings, and so we try to anticipate this beforehand and make corrections."

Metal 3 - Craftsman, Press

"If parts are not of the desired quality from the very beginning, they will never result in good optical frames."

Metal 4 - Craftsman, Precision Cutting

"Accuracy is kept to within plus or minus 0.02 mm."

Metal 6 - Craftsman, Polishing

"The cleaner the glasses are, the dirtier my hands become."

Metal 7 - Craftsman, Inspection

"We must prevent glasses breaking once they are in the hands of the customer, and we must prevent it right here."

Metal 8 - Craftsman, Surface Treatment

"Our metal frames are shipped with solid, consistent plating. I sincerely believe that no one can beat our quality frames."

Metal 9 - Craftsman, Finishing

"Many people are involved in the production of a single pair of glasses, and each and every one of them strive not to put any of their fellow craftsmen to shame."

Plastic 1 - Craftsman, Design

"The key is to come up with designs that make the user require a little courage when making their purchase."

Plastic 2 - Craftsman, Cutting

"The frame represents the face of glasses, and is tailor cut according to the materials used."

Plastic 3 - Craftsman, Filing

"It is a joy to see a single file produce the expected roundness."

Plastic 4 - Craftsman, Nose Pad

"There are subtle differences in the sounds produced when removing soft and hard materials."

Plastic 5 - Craftsman, Temples

"We try to find the best location to insert the cores so that they go in straight."

Plastic 6 - Craftsman, Finishing

"I am most careful of how fluorescent light is reflected on frames."